Waukesha-Hesselman (added March 2012)

Waukesha-Hesselman Oil Engines

What are they and why were they made?

The WAUKESHA-HESSELMAN OIL ENGINE featured fuel injection and spark ignition which gave it a multi-fuel capability. It was designed by Jonas Hesselman and was built by WAUKESHA MOTOR COMPANY from 1932 until 1951.

See both the ignition system and the fuel injection system on our 6WAKH unit on the virtual tour of the Training Center by clicking on the 6WAKH photo below right.

|

| 6WAKH |

Click to visit Training Center display

|

The petroleum refinement and distribution industry was in its infancy in those years. Fuel supplies for many parts of the world were limited and inconsistent in content and availability. The HESSELMAN engine family was a perfect match for its time, being designed to run on most any application on most any refined oil. Whatever the port or station had for fuel, it was 'fill er up 'and we're on our way.

The HESSELMAN was the preferred alternative engine of its era. WAUKESHA MOTOR COMPANY built more than 7 times more Hesselmans than diesel production in those years.

Waukesha-Hesselman

The Waukesha-Hesselman engine is a solid injection, moderate compression, spark ignition oil engine manufactured under the American Hesselman patents for use in automotive and industrial service. It is more than two years since the first one was manufactured in America. It was for use with a portable air compressor. Since then Waukesha-Hesselman engines have found their way into industrial machinery in every civilized country. They are so simple that any operator who has had experience with gasoline engines will find the Hesselman easy to understand and take care of. Waukesha-Hesselman engines are built in sizes that range from 20 hp. to 300 hp., based on the Internal Combustion Engine Institute Code for "Standard Net Stripped Engine" Ratings. They weigh the same as a gasoline engine of the same size plus 30-50 pounds of injection apparatus.

|

| From General Instructions Form 908N Edition 15, November 1957 |

Not a Semi-Diesel

The Waukesha-Hesselman oil engine is in no sense a semi-Diesel. It does not require hot-bulb or hot-spot preliminary heating to start it. No more warm·up is required than with a gasoline engine. and, although it receives its fuel charge by solid injection, it starts as readily as a gasoline engine because of its electric ignition. It burns its fuel as cleanly, and it runs as smoothly as a gasoline engine; size for size, develops the equivalent power. It is no more sensitive to conditions of cylinder and ring wear, or to valve seating, than a gasoline engine. It has none of the high pressure problems of the semi-Diesels or self-ignition engines. Furthermore, normal variations in the ignition characteristics of commercial fuels have little or no effect on the Hesselman oil engines.

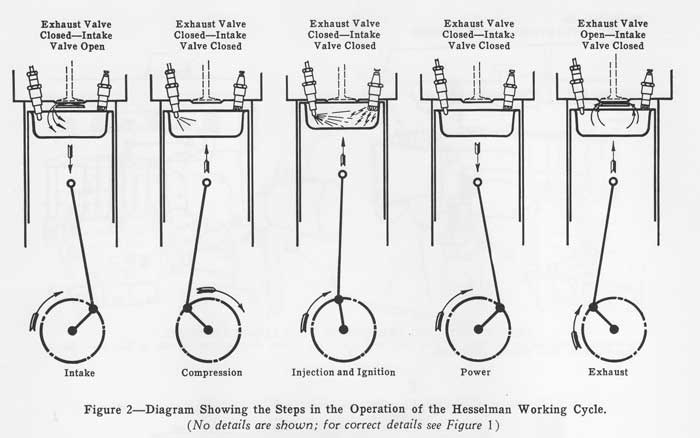

How it Works

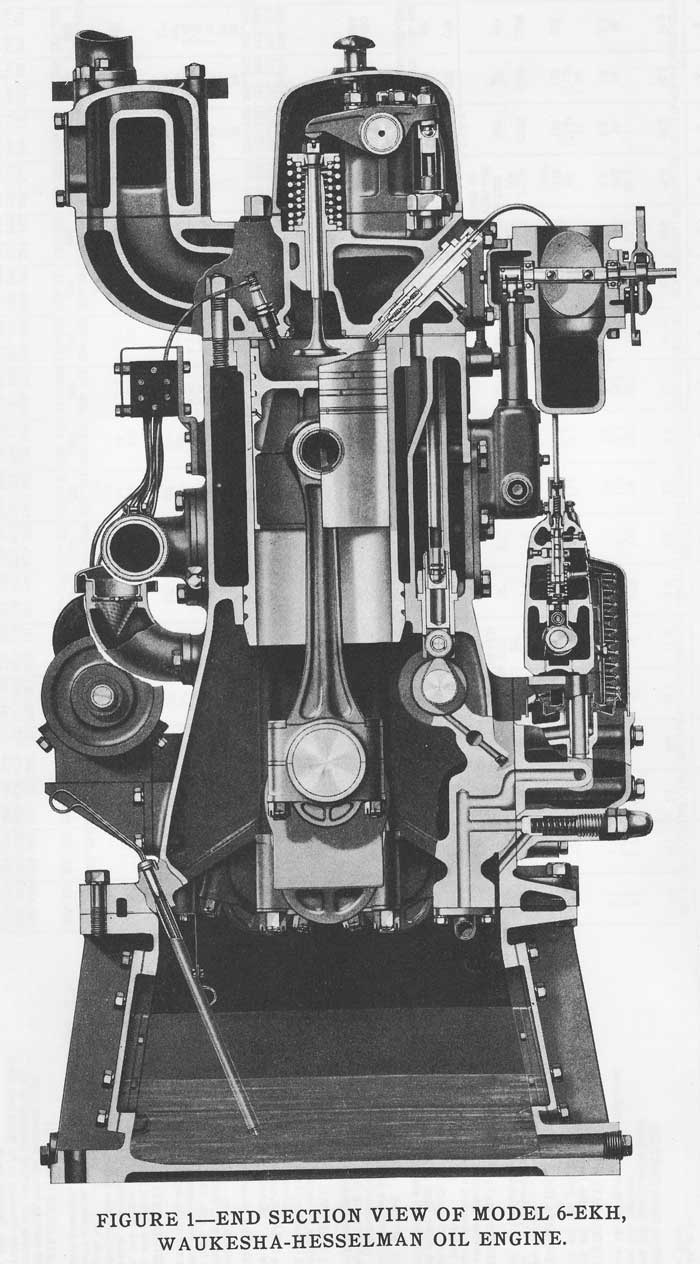

The Hesselman cycle is as easy to understand as the four-cycle gasoline engine. On the intake stroke, air alone is admitted to the cylinder--no fuel until after compression. The charge of air is compressed to only about 125 pounds, and just before the end of the compression stroke, the fuel is injected by a Diesel type injection pump. Owing to the special shape of the combustion chamber, the air is compressed in a definite turbulence pattern which picks up the finely atomized fuel from the injector, thoroughly mixes with it, and sweeps past the spark plug which, at that moment, ignites the charge. This produces the power on the power stroke immediately following. Near the end of the power stroke, the exhaust valve opens and, as the piston returns, the cylinder is scavenged, and prepared for a repetition of the cycle. Neither the air nor the fuel is preheated--an essential requirement for carbureted distillate-type of engine-so that the delivered power and volumetric efficiency are correspondingly high.

|

| From General Instructions Form 908N Edition 15, November 1957 |

Suitable Fuels

The first consideration in the selection of fuels for Hesselman Engines is that they must be clean. Raw crudes, bunker oils, reclaimed drainings and similar fuels sometimes burned in big bore, slow-speed engines and in powerhouse furnaces are no more suitable for a Hesselman Engine than for any other modern .. high speed" oil engine. Most reliable makers' No. 2 or No. 3 furnace oils, as well as their No. 1, commercial distillate, and kerosene, can be used, although their cost will usually eliminate these lighter fuels. Fuels with a high carbon, gum, acid, or sulphur content should be avoided the same as with any other solid injection engine. Those that do not flow freely at the surrounding operating temperatures should naturally be avoided. If No. 1 furnace oil, distillates, or kerosenes are used, the lack of lubrication for the injection apparatus may be made up by the addition of a small amount of light engine oil in the fuel tank. In addition to liquid fuels, a simple change of external parts, manifolds, gas carburetors and attachments--less than a day's work--adapts these engines to burn Butane or natural gas. The practical significance of these broad specifications is that Hesselman engines can utilize fuels obtainable almost anywhere in the world.

|

| Bulletin 1215, August 1940 |

| Click on image to open PDF of bulletin (845 KB) |

Excerpted from Bulletin 945-A, June 1935 and General Instructions 908-N Edition 15, November 1957

Copyright © 2012 Waukesha Engine Historical Society, Inc. All rights reserved