The Motor Works - Part 6 (added August 2014)

Waukesha Motor Co. expands diesel, propane products

|

JOHN SCHOENKNECHT |

Many members of the workforce served their country in the war. Some of them wrote to Waukesha Motors to tell their experiences. George Graham’s account was published in the company newsletter.

“George Graham sees ’em in action”

“George Graham, who was in the Shipping Room with John Zollner, has been in the South Pacific almost two years, and for a Seaman 1c (first class) seems to have had quite a lot of shore duty. He has had close enough contact with our motors on construction and airport work to qualify as a Seabee (no offense, George). He writes.

‘My first job was on Eniwetok when that was taken, and I have a bronze star for that. Was there seven months, and that was seven hard months as it got as hot as 140 degrees in the shade and there was no shade. I was in charge of two of your FC motors here with a 4-in. Jaeger pump, and they were run 24 hours a day for the first five months that we were there. And when we came here they were brought along and are still running.’

‘I see a lot of the ICK's that are used for the B-29s, and we have some of the larger ones, so you can see wherever we go there is always a Waukesha motor, and I often wonder if they are some that I had worked on.’

‘I don’t suppose that I will know the plant when I get back with that new building that I hear is going up.’”

A 1945 Freeman article mentioned that many foreign visitors came to see the plant to learn more about the engines they saw used during the war.

The same article mentioned that new distribution centers were being constructed around the country so that they could be stocked with parts. And it clarified the uses of Waukesha motors.

“Waukesha engines and power units are used in six major markets – the automotive field, including trucks, buses and fire equipment: the industrial field including the construction of buildings, roads, excavating, dredging material, all kinds of mining operations, and many others: the oil field market including drilling and producing: the logging and timber market where Waukeshas are used in yarders, hoists, saw mills and the huge trucks that haul the logs from the forests to the mills: the agricultural market for many kinds of farm machinery and equipment, irrigation pumps, grain and feed, mills, cotton gins, and all kinds of materials handling: and finally, the refrigeration market of truck and bus cooling, railway air conditioning, and railway electric generating sets.”

|

|

| Photo from the Waukesha County Museum | Photo from the John Schoenknecht collection at the Waukesha County Museum |

| 1948 – Overall view of the plant back to work on peacetime motors.These model 145 motors are being tested. | A worker works on a lathe in 1947. |

Post-war work continued

Despite canceled government contracts, the company continued to grow after the war. It developed a new line of efficient diesel motors that were put to work in the oil fields. Employees grew to number 2,100 in 1947.

An interesting Freeman article from Sept. 10, 1948, took the reader on a tour of the parts and service department. When an order was received by mail, it needed to have the serial number of the motor included. From that number, a worker located the correct part and bin number. The order was then sent on a conveyor belt where another worker located the part(s) needed. The conveyor belt then took the part to the shipping department, where it was boxed and sent on its way.

The following month, another article told of how many precision tools were used to assemble and produce parts. The old-timers, men who had worked 10 or more years, were particularly helpful in making sure the parts were created with precision.

Another interesting article in October 1949 told about what was needed to keep the plant running. Each day 22,000 kilowatt hours of electricity were used to power machinery, exhaust and ventilation systems and motors. During cold weather, 300 tons of coal were used each week to feed the five steam boilers that heated the plant. And each month 5,000,000 gallons of water passed through the plant. Heating, ventilation, firefighting equipment as well as care of the buildings and grounds was under the supervision of Elmer Lewis, a man with 38 years of experience.

The plant had more fire hoses than the Waukesha Fire Department and the entire plant was equipped with sprinklers. Two first aid stations were available in case of injury.

The plant was patrolled by a force of 10 security guards, who also watched the seven acres of parking lots.

An article by Freeman staff writer May Merrill in November 1948 told of the tool design department. Waukesha Motor designed and produced special tools needed to build the parts and the engines. A special team studied the new designs for engines and decided what types of tools would be needed and how they would be built. This team also decided how long each task would take, based on 20 years of time keeping statistics.

The office staff was highlighted in a Freeman article from Jan. 14, 1949. An early form of computer technology was described in the story. The machine was called the multiplier. It was able to multiply a six-digit number by another six-digit number at the rate of 100 answers a minute. The brains of the machine was a box 4 feet by 3 feet by 1 foot. It was connected by a one inch thick cable to a series of punch cards.

An accounting machine was about the size of a refrigerator, but it “contains 16 adding machines and can do everything but roll a cigarette.”

At the Society of Automotive Engineers banquet on June 13, 1949, Sir Harry Ricardo of Shoreham, England, was awarded the Harry Horning Memorial Award. It was fitting that Ricardo was finally given this award, named after his friend and business partner Harry Horning. The award was established in 1936 in Horning’s memory and consisted of a medal and a cash prize.

In 1949, the term Enginator was introduced to market an engine-generator unit. This unit was designed to supply power to the air conditioners of sleek, streamlined trains. The unit was located under the car and could be installed in about 35 minutes. It could easily be pulled in and out for maintenance and repair. One of the unique features was that it turned itself on and off according to the demand of the car.

|

|

|

| Freeman photo from the Waukesha County Museum | Freeman photo from the Waukesha County Museum | Photo from the John Schoenknecht collection at the Waukesha County Museum |

| November 1950 – A new 100,000-gallon water tower was constructed on “Motor Hill” across from the plant. | Frank Leberman | The shipping department preparing parts for shipping in 1952. |

The 1950s

During this decade, the company focused on both motors for moving vehicles and also motors that stood still and operated machinery or generated power. During this decade an important milestone was reached.

In 1950, the company began a long standing partnership with Clark Equipment, a company that made forklifts. The company purchased nearly 10,000 motors in the 1950s. Cliff Borgstrom of the Waukesha Engine Historical Society was sent to check out the quality assurance of the new company.

In 1950, a new 100,000-gallon water tower was erected across from the company on St. Paul Avenue. When new pipes were laid to the plant, the tower provided additional protection from fires. It replaced an older 60,000-gallon wooden tank.

Although the diesel line of motors was expanded and improved in 1951, an interesting article in the Nov. 4, 1950, Freeman told another story. “Waukesha Motor Company Helps Spread Use of New, Cheap Fuel Called Propane,” read the headline. It went on to explain that propane was removed from oil as a byproduct and was very inexpensive. Propane was used in most of the refrigeration units on railroad cars, but the company also built units for lighting that used propane.

In 1952, the company introduced its first turbocharged diesel. The use of turbocharging resulted in increased acceleration, cleaner burning, a reserve of power and improved overall economy.

In June 1952, ground was broken for a new 18,000- square-foot research facility. This allowed the company to bring all of the research work into one spot, and freed other spaces for storage and production. The new facility opened in 1953.

The year 1954 saw another landmark as the first V-12 motors were introduced.

|

|

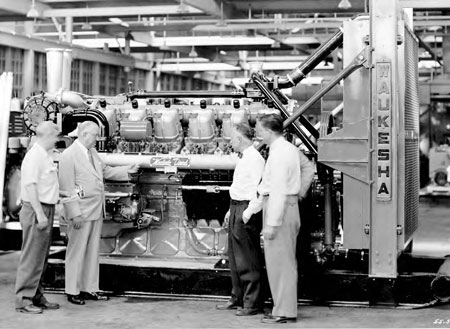

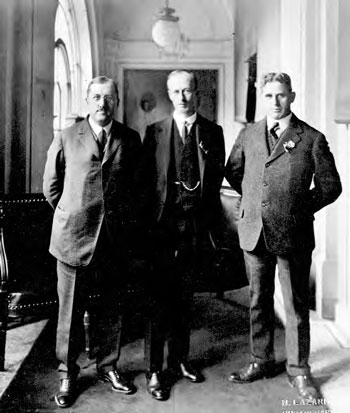

| Photo from the Waukesha County Museum | Photo from the Waukesha County Museum |

| 1955 – James DeLong, second from left, looking at a model VLRD | Harry Horning on left, Harry Ricardo in center and an unknown man on right. Ricardo received the Harry Horning Award in 1949. |

Waukesha’s Enginator used in railroad passenger cars was a fine product, but railroad passenger service was rapidly decreasing in the 1950s. In 1955, the company introduced the “Diesel- Icer” which was to be used to refrigerate box cars, or “reefers.” The company equipped a car at its plant, and was the first to do so, but because of competition with Ford and Westinghouse, Waukesha’s unit never caught on. The refrigeration arm of the company was repurposed in 1956 and named the Special Products Division. It concentrated on stationary power units.

But the year 1956 was also the 50th anniversary for the company. During the year, a Model 135DK was shipped to the Electric Service Engineering Co. It bore serial number 1,000,000.

A June 4, 1956, Freeman carried a photo of “Motor Hill Terrace.” This was a complex of surplus housing units that were constructed across from the factory during and after World War II. The complex helped ease a housing shortage. In 1960 the units were sold at auction and moved. Rumor has it that there are still a few of them in Waukesha.

In 1957, the company acquired the Climax Motor Co. of Clinton, Iowa.

In 1958, Westinghouse licensed Waukesha Motors to build LeRoi engines under the Roiline brand name.

In 1959, innovations in electronic control of motors was introduced. “Engomatic” controls were introduced and installed. This allowed a motor to be started by radio signal, time clock, thermostat or liquid level. This came in handy when an operator was not on duty and was very useful during power outages or remote locations.

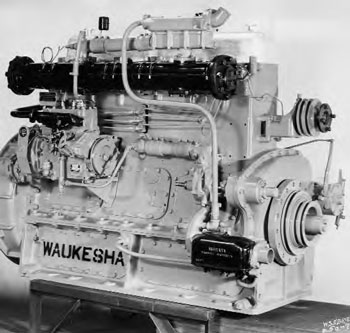

|

|

| Photo from the John Schoenknecht collection at the Waukesha County Museum | Freeman photo from the Waukesha County Museum |

| 1950 – Model 6NKD. | Nov. 28, 1959 – Congratulating Tony Herzberg (seated) were co-workers, from left, S.J.“Brownie” Schwartz, Anton Spelich, John Martin and John Suttner. |

In 1959, 70-year old Tony Herzberg retired from his job as plant superintendent. He worked for the company for 32 years. He had a reputation as a human dynamo and also as a bit of a mischief maker. In a Nov. 28, 1959, Freeman article, he recalled a time when he filled a bag with brass shavings, intending to hit a fellow employee with it. Instead, the bag hit the ceiling and spilled its contents on the plant superintendent, A. W. Dietzel. Tony offered to resign, but his resignation was refused. Before working at the Motor Company, Herzberg was a semi-pro and pro baseball (a farm team in Green Bay for the Detroit Tigers) and semi-pro football player (13 years for the Racine Monarchs). He invented a universal drill head and a transfer machine which turned out engine parts on an automatic basis. He even owned his own company in Milwaukee.

Frank J. Leberman also retired from the company in the 1950s. According to an undated Freeman article, he started working when the plant was in its original location on North Street. He recalled that in the early days there were 13 or 14 employees. They often worked until the wee hours of the morning to finish a job. When that happened, Sam Perkins went downtown and returned in a horse-drawn cab with a midnight snack of coffee, sandwiches and pie. After the break, the men went back to work. Leberman lived on Main Street with his wife and nine children. He planned to rest after his retirement.

Many other workers and executives retired from the company in the 1950s, all with many years behind them. This was the true testament to the comradeship and loyalty of Waukesha Motors employees.

(John Schoenknecht can be reached at thbolt@wi.rr.com.)

This article was originally published in the Tuesday, February 18, 2014 issue of The Freeman Waukesha County's newspaper.

Copyright © 2014 Waukesha Engine Historical Society, Inc. All rights reserved